Alistair Group Security Measures

Alistair Group prioritises the safety and security of our client’s cargo. We have implemented multiple physical safety and security measures and pride ourselves on the protocols and technological developments that protect our client’s supply chain holistically.

PHYSICAL WAREHOUSING SECURITY:

When it comes to warehouse security, it is needed to implement security measures both inside and outside the facility. External-facing warehouse security systems, known as perimeter security, are used to defend entry points and the property line – often focusing on limiting access. Internal warehouse security measures help identify those who have breached the external security measures, focusing on capturing evidence. It’s important to have layered security measures to protect the facility in its entirety. Below is a list of physical safety and security measures Alistair Group has implemented:

- Top of the range Facilities

- The quality and standard of our buildings are top of the range.

- The building infrastructure is in pristine condition and we offer indoor/covered storage solutions to minimise the risk of theft and weather damage.

- Approved Warehouse

- With many of our client’s cargo being financed from Europe and maintaining ownership of the cargo till exported, it’s important to ensure all banks are familiar with our live stock systems, giving them peace of mind that data is accurate at all times.

- Alistair Group is an approved warehouse for all major trade finance banks.

- CCTV

- Alistair Group has CCTV integrated cameras throughout all facilities in DAR and Durban with visibility over all warehouse spaces, yard spaces, entry gates and weighbridges

- CCTV monitoring, allows us to readily monitor even the remotest areas of our warehouse— always being alert to what’s going on throughout the facility.

- Security SOP (Standard operating procedure)

- Alistair Group has developed and implemented security SOPs to manage all truck, staff and cargo movement both receiving and dispatching/packing of cargo.

- These SOPs include:

- High-value metals/minerals receipt into warehouses

- High-value metals/minerals export packing

- Gate security procedure (receiving/dispatch)

- Port shunt and escorting high-valued metals and minerals

- Security Personel

- We have visible security on site 24 hours to monitor all operational movement throughout the yard space, night operations and warehouse operations.

- CCTV is an effective way to remain informed however we prefer to also have feet on the ground to provide heightened industrial security.

- Alarm Response And Verification

- All Alistair Group facilities are fitted with alarm systems and response units on stand bye from a third-party security company.

- Our Alarm systems are accompanied by protocols stipulating how to respond promptly to any alarms that go off, and to verify when there is a real security threat.

- Secure Entrance Points

- Due to the high volume of feet that commonly enter our warehousing facility, individuals and trucks have to go through our controlled entry points. At each point of entry, the identification and verification documentation of each driver and truck is assessed before access to our warehouse is granted. These records are monitored and stored should they be required in the event of an incident.

SECURITY IN THE SUPPLY CHAIN:

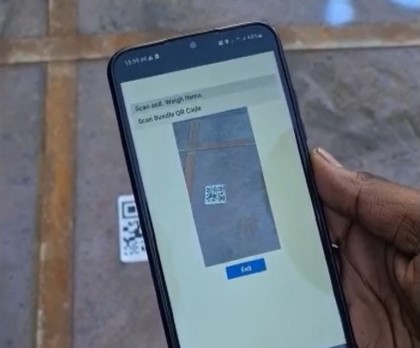

When talking about security it is important to delve into the topic of visibility. To ensure the utmost security of cargo we would need constant and controlled visibility of the cargo as it moves through the supply chain. Alistair Group has developed and implemented a multitude of security measures that heightens our and our client’s visibility of their cargo. Giving them the ability to constantly monitor live updates of the cargo’s whereabouts. This technology has allowed Alistair Group to reduce human error and man-hours required to operate in a timely and effective manner.

Our own cloud-based Warehouse Management System (WMS) is used to provide a fully integrated multi-location solution, and can easily adapt to our client visibility needs. Alistair Group technology allows for the tracking of our client’s cargo on a per-bundle basis – providing visibility into each bundle throughout the stages of transportation. We provide our clients with real-time reporting and alerting (including an advanced report builder), as well as barcode scanning for rapid and accurate check-in / out of inventory items. A lot of our resources have been focused on developing this visibility and getting our dashboards to intuitively provide real-time information which is accurate and dependable; providing our customers with ease of mind about the safety, security and warehouses of their cargo.

The main two areas of visibility that Alistair Group provides our clients:

- Live warehouse management systems

- Live warehouse management systems show real-time receiving and removal of cargo throughout all our facilities. Read more about it HERE.

- Fully integrated logistics

- Fully integrated logistics between road, warehouse and vessel with 100% of Alistair’s cargo moving from our trucks to the warehouse to the port. Tech integration ensures clients always have live data of where their cargo is in the chain and where it transitions from different modes of transport into the warehouse. Read more about it HERE.

Daniel du Plooy | Head of Warehsousing | 04 July 2022